การกัด CNC (Computer Numerical Control) เป็นหนึ่งในเทคนิคที่จำเป็นและใช้กันอย่างแพร่หลายมากที่สุดในการผลิตสมัยใหม่ ด้วยความสามารถในการสร้างชิ้นส่วนที่มีความแม่นยำสูงและซับซ้อน จึงได้ปฏิวัติอุตสาหกรรมต่างๆ ตั้งแต่อวกาศไปจนถึงยานยนต์ อุปกรณ์ทางการแพทย์ และอื่นๆ ซึ่งแตกต่างจากการกัดด้วยมือแบบเดิมๆ การกัด CNC ใช้คำสั่งที่สร้างโดยคอมพิวเตอร์เพื่อควบคุมการเคลื่อนไหวของเครื่องมืออย่างแม่นยำ ทำให้สามารถผลิตชิ้นงานที่ซับซ้อนได้อย่างมีประสิทธิภาพสูงและลดข้อผิดพลาดของมนุษย์ให้เหลือน้อยที่สุด

อย่างไรก็ตาม เนื่องจากมีเครื่องกัด CNC หลายประเภทให้เลือก การเลือกเครื่องที่เหมาะสมสำหรับงานเฉพาะอาจเป็นเรื่องยาก เครื่องกัดแต่ละประเภทมีคุณลักษณะเฉพาะตัว ทำให้เหมาะกับการใช้งานเฉพาะ ไม่ว่าคุณจะทำงานกับชิ้นส่วนขนาดเล็กที่ซับซ้อนหรือชิ้นส่วนขนาดใหญ่ที่รับน้ำหนักมาก ในบทความนี้ เราจะเจาะลึกเครื่องกัด CNC ประเภทต่างๆ พร้อมอธิบายข้อดีเฉพาะและการใช้งานเฉพาะของเครื่องจักรแต่ละประเภทในการผลิตสมัยใหม่ เมื่อเข้าใจถึงความสามารถของเครื่องจักรแล้ว คุณจะสามารถตัดสินใจได้ดีขึ้นว่าเครื่องจักรใดจะตอบสนองความต้องการของกระบวนการผลิตของคุณได้ดีที่สุด

นี่คือรายการโดยละเอียดของ 12 ประเภทที่พบบ่อยที่สุด เครื่องกัดซีเอ็นซีพร้อมการใช้งานและข้อดี:

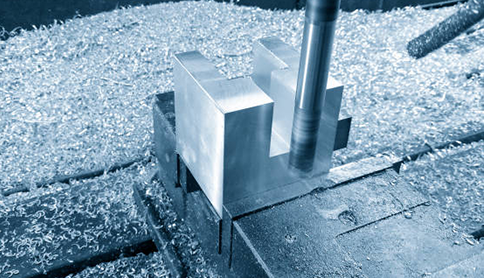

เครื่องกัดแนวตั้ง CNC เป็นเครื่องกัด CNC ที่นิยมใช้กันมากที่สุดชนิดหนึ่ง เครื่องนี้ประกอบด้วยแกนหมุนแนวตั้งที่เคลื่อนขึ้นและลง ชิ้นงานมักจะยึดกับโต๊ะด้านล่างแกนหมุน โดยเครื่องมือตัดจะเคลื่อนไปตามแกนแนวตั้งเพื่อขึ้นรูปหรือตัดวัสดุ

● การวางแนวแกนหมุนแนวตั้ง:เครื่องมือตัดติดตั้งบนแกนหมุนแนวตั้ง ซึ่งเหมาะอย่างยิ่งสำหรับการเจาะ การเจาะคว้าน และการกลึงผิว การติดตั้งในแนวตั้งช่วยให้เข้าถึงวัสดุได้ง่าย

● การออกแบบที่กะทัดรัด:เครื่องบดแนวตั้งมีแนวโน้มที่จะใช้พื้นที่น้อยกว่าเครื่องจักรแนวนอน จึงเหมาะกับโรงงานขนาดเล็กหรือโรงงานที่มีพื้นที่จำกัด

● ความสะดวกในการใช้งาน:ผู้ปฏิบัติงานสามารถตรวจสอบและควบคุมกระบวนการตัดได้อย่างง่ายดายเนื่องจากมองเห็นพื้นที่การตัดได้ชัดเจน

● ความแม่นยำสูง:เครื่องกัด CNC แนวตั้งเหมาะอย่างยิ่งสำหรับการตัดเฉือนชิ้นส่วนที่มีคุณลักษณะซับซ้อนอย่างแม่นยำ เครื่องกัดประเภทนี้สามารถสร้างรายละเอียดที่ละเอียดอ่อนและค่าความคลาดเคลื่อนที่แคบได้

● ความอเนกประสงค์:สามารถใช้กับวัสดุได้หลากหลายประเภท เช่น โลหะ พลาสติก และไม้ จึงเหมาะสำหรับอุตสาหกรรมต่างๆ เช่น ยานยนต์ อิเล็กทรอนิกส์ และอุปกรณ์ทางการแพทย์

● คุ้มค่าคุ้มราคา:เมื่อเทียบกับเครื่องจักรอื่น เครื่องบดแนวตั้งมักจะมีราคาไม่แพง จึงเหมาะกับธุรกิจขนาดเล็กถึงขนาดกลาง

● การพัฒนาต้นแบบ:เหมาะอย่างยิ่งสำหรับการสร้างต้นแบบ เนื่องจากสามารถกลึงรูปทรงเรขาคณิตที่ซับซ้อนได้อย่างรวดเร็ว

● การผลิตขนาดเล็กถึงขนาดกลาง:ใช้ในอุตสาหกรรมต่างๆ เช่น อุปกรณ์การแพทย์ ยานยนต์ และการบินและอวกาศ เพื่อผลิตชิ้นส่วนที่กำหนดเองหรือการผลิตจำนวนน้อย

เครื่องกัดซีเอ็นซีแนวนอนมีแกนหมุนแนวนอนที่ช่วยให้กระบวนการตัดมีเสถียรภาพมากกว่าเครื่องแนวตั้ง การออกแบบแนวนอนช่วยให้ตัดเศษโลหะได้เร็วขึ้นและมีประสิทธิภาพมากขึ้น ซึ่งเป็นสิ่งสำคัญสำหรับชิ้นส่วนขนาดใหญ่หรือหนัก

● แกนหมุนแนวนอน:เครื่องมือนี้ติดตั้งไว้บนแกนหมุนแนวนอน ซึ่งช่วยส่งเสริมการกำจัดเศษวัสดุและเศษวัสดุอย่างมีประสิทธิภาพในระหว่างกระบวนการตัดเฉือน

● ตัวเลือกเครื่องมือหลากหลาย:เครื่องบดแนวนอนมักจะมาพร้อมกับที่จับเครื่องมือเพิ่มเติม ช่วยให้ผู้ปฏิบัติงานสามารถใช้เครื่องมือหลายชิ้นพร้อมกันได้ ซึ่งจะช่วยปรับปรุงประสิทธิภาพการผลิต

● การกำจัดชิปที่ดีขึ้น:การออกแบบแนวนอนช่วยให้ระบายน้ำและกำจัดเศษวัสดุได้ดีขึ้น จึงเหมาะกับการตัดเฉือนวัสดุปริมาณมาก เช่น เหล็กหรือไททาเนียม

● เพิ่มเสถียรภาพ:การตั้งค่าแนวนอนทำให้เครื่องจักรเหล่านี้มีเสถียรภาพมากขึ้น โดยเฉพาะอย่างยิ่งเมื่อต้องกลึงชิ้นงานขนาดใหญ่หรือหนักมาก

● การกลึงที่รวดเร็วยิ่งขึ้น:เนื่องจากเครื่องบดแนวนอนมีความสามารถในการขจัดเศษโลหะอย่างมีประสิทธิภาพ จึงมีความเร็วในการตัดที่เร็วกว่า ทำให้เหมาะอย่างยิ่งสำหรับการผลิตปริมาณมาก

● ลดเวลาในการตั้งค่า:เครื่องกัด CNC แนวนอนมักประกอบด้วยเครื่องเปลี่ยนเครื่องมืออัตโนมัติและสถานีเครื่องมือหลายสถานี ซึ่งช่วยลดเวลาที่ใช้ในการสลับเครื่องมือและการตั้งค่าเครื่องจักร

● การผลิตจำนวนมาก:มักใช้สำหรับอุตสาหกรรมที่ต้องการการผลิตปริมาณสูง เช่น การผลิตยานยนต์และชิ้นส่วนอากาศยาน

● ส่วนประกอบขนาดใหญ่:ความเสถียรและกำลังของเครื่องจักร CNC แนวนอนทำให้เครื่องนี้เหมาะอย่างยิ่งสำหรับการตัดเฉือนชิ้นส่วนขนาดใหญ่ เช่น บล็อกเครื่องยนต์และชิ้นส่วนอุปกรณ์หนัก

เครื่องกัดซีเอ็นซี 5 แกนมีการพัฒนาที่ก้าวล้ำกว่าเครื่องกัด 3 แกนแบบเดิมอย่างมาก โดยให้เครื่องมือสามารถเคลื่อนที่ไปตามแกนทั้ง 5 แกน ได้แก่ แกนเชิงเส้น 3 แกน (X, Y, Z) และแกนหมุน 2 แกน (A และ B) การทำงานนี้ทำให้เครื่องสามารถเข้าใกล้ชิ้นงานได้จากแทบทุกมุม จึงสามารถสร้างรูปทรงเรขาคณิตที่ซับซ้อนได้อย่างแม่นยำ

● การเคลื่อนไหวห้าแกน:เครื่องจักรนี้สามารถหมุนชิ้นงานได้ 2 แกน นอกเหนือจากการเคลื่อนที่เชิงเส้นแบบ X, Y และ Z ตามปกติ ซึ่งทำให้เครื่องจักรสามารถจัดการกับรูปทรงที่ซับซ้อนซึ่งปกติแล้วต้องเปลี่ยนตำแหน่งใหม่ได้

● ลดความต้องการในการเปลี่ยนตำแหน่ง:ความสามารถในการเข้าถึงชิ้นส่วนทุกมุมในการตั้งค่าเดียวช่วยลดเวลาที่ต้องใช้ในการจัดการชิ้นส่วนและเพิ่มประสิทธิภาพการตัดเฉือนได้อย่างมาก

● ความแม่นยำการเคลื่อนไหวหลายแกนช่วยให้มั่นใจได้ว่าชิ้นส่วนได้รับการกลึงด้วยความแม่นยำสูง แม้ในการใช้งานที่ท้าทาย

● เรขาคณิตที่ซับซ้อน:เหมาะอย่างยิ่งสำหรับการกลึงรูปร่างที่ซับซ้อนและละเอียดอ่อน เช่น ใบพัดกังหันหรือส่วนประกอบของอวกาศ ซึ่งไม่สามารถสร้างได้ด้วยเครื่องกัดแบบดั้งเดิม

● ความแม่นยำสูงกว่า:ด้วยการตั้งค่าที่น้อยลง ความแม่นยำของผลิตภัณฑ์สำเร็จรูปจึงเพิ่มขึ้น และความเสี่ยงต่อข้อผิดพลาดอันเกิดจากการปรับเปลี่ยนตำแหน่งก็ลดลง

● ประสิทธิภาพด้านเวลาและต้นทุน:ลดความจำเป็นในการตั้งค่าและการใช้งานเครื่องจักรหลายเครื่อง จึงช่วยลดเวลาในรอบการทำงานและต้นทุนแรงงานได้อย่างมาก

● ส่วนประกอบการบินและอวกาศ:ใช้กันอย่างแพร่หลายในการตัดเฉือนชิ้นส่วนอากาศยาน เช่น ใบพัดกังหัน ซึ่งต้องมีรูปทรงเรขาคณิตที่ซับซ้อนและความแม่นยำสูง

● อุปกรณ์ทางการแพทย์:เหมาะอย่างยิ่งสำหรับการผลิตส่วนประกอบทางการแพทย์ที่มีความแม่นยำสูง เช่น ชิ้นส่วนปลูกถ่ายและอุปกรณ์เทียม

● ยานยนต์และวิศวกรรม:จำเป็นสำหรับยานยนต์และการใช้งานด้านวิศวกรรมสมรรถนะสูงที่ต้องมีความทนทานสูงและมีรูปร่างที่ซับซ้อน

เครื่องกัด CNC แบบป้อมปืนมีป้อมปืนหมุนที่ยึดเครื่องมือได้หลายชิ้น ช่วยให้เปลี่ยนเครื่องมือได้อย่างรวดเร็วและมีความสามารถในการตัดเฉือนที่ยืดหยุ่นสูง การออกแบบนี้เหมาะอย่างยิ่งสำหรับงานที่ต้องใช้การทำงานหลายอย่างโดยไม่ต้องเปลี่ยนเครื่องมืออยู่ตลอดเวลา

● ป้อมปืนหมุนได้:ป้อมปืนบรรจุเครื่องมือตัดหลายชิ้น ช่วยให้เครื่องจักรสามารถสลับระหว่างเครื่องมือได้โดยอัตโนมัติระหว่างการทำงาน โดยไม่จำเป็นต้องเปลี่ยนเครื่องมือด้วยตนเอง

● ความยืดหยุ่น:เครื่องกลึงป้อมปืนสามารถใช้สำหรับงานต่างๆ มากมาย เช่น การเจาะ การต๊าป และการกัด ซึ่งมีการใช้งานที่หลากหลายสำหรับงานที่แตกต่างกัน

● ขนาดกะทัดรัด:เมื่อเทียบกับเครื่อง CNC อื่นๆ เครื่องกลึงป้อมปืนมักจะกะทัดรัดกว่า ทำให้เหมาะกับโรงงานขนาดเล็ก

● เปลี่ยนเครื่องมืออย่างรวดเร็ว:ความสามารถในการสลับระหว่างเครื่องมือโดยอัตโนมัติช่วยลดเวลาหยุดทำงานและเพิ่มประสิทธิภาพโดยรวม

● มัลติฟังก์ชัน:ให้ความยืดหยุ่นในการดำเนินการหลายอย่างโดยไม่ต้องใช้เครื่องจักรหลายเครื่อง ทำให้ประหยัดต้นทุนและมีประสิทธิภาพ

● เหมาะสำหรับการผลิตขนาดกลาง:มีประโยชน์มากโดยเฉพาะอย่างยิ่งสำหรับการผลิตขนาดเล็กถึงขนาดกลางที่ต้องมีการดำเนินการหลายอย่างบนชิ้นส่วนเดียวกัน

● ยานยนต์และอวกาศ:ใช้สำหรับการผลิตชิ้นส่วนจำนวนน้อยถึงปานกลางที่มีคุณสมบัติแตกต่างกัน

● การผลิตแบบกำหนดเอง:เหมาะอย่างยิ่งสำหรับชิ้นส่วนที่กำหนดเองและมีปริมาณน้อย เนื่องจากป้อมปืนสามารถเปลี่ยนเครื่องมือเพื่อจัดการงานต่างๆ ได้อย่างรวดเร็ว

เครื่อง CNC Bridge Mill มีลักษณะเป็นสะพานที่มีเสาขนาดใหญ่ 2 ต้นที่ยึดเครื่องมือไว้ ทำให้มีความแข็งแรงและมั่นคงเป็นอย่างยิ่ง โครงสร้างนี้มีประโยชน์อย่างยิ่งสำหรับชิ้นส่วนขนาดใหญ่และหนักที่ต้องกลึงด้วยความแม่นยำสูง

คุณสมบัติหลักของเครื่อง CNC Bridge Mill:

● การออกแบบสะพาน:ชิ้นงานจะวางอยู่บนแท่นคงที่ในขณะที่หัวเครื่องมือจะขยายไปทั่วชิ้นส่วน ส่งผลให้มีเสถียรภาพและความแม่นยำเป็นเลิศ

● งานหนัก:สามารถรองรับวัสดุขนาดใหญ่และหนัก เช่น โลหะและวัสดุผสม จึงเหมาะกับการใช้งานที่มีความต้องการสูง

● ความแม่นยำสูง:แม้ว่าจะมีขนาดใหญ่ แต่เครื่องจักรเหล่านี้ก็สามารถผลิตงานตัดเฉือนที่แม่นยำและมีคุณภาพสูงได้

● ความเสถียรสำหรับชิ้นส่วนขนาดใหญ่:การออกแบบที่แข็งแกร่งช่วยให้สามารถตัดเฉือนชิ้นส่วนขนาดใหญ่และซับซ้อนได้โดยไม่กระทบความแม่นยำ

● ความสามารถในการรับน้ำหนักสูง:สามารถรองรับน้ำหนักได้มาก ซึ่งทำให้เหมาะกับงานการผลิตที่ต้องใช้แรงหนัก

● ลดการสั่นสะเทือนโครงสร้างสะพานช่วยลดการสั่นสะเทือนระหว่างการตัดเฉือนซึ่งช่วยเพิ่มคุณภาพโดยรวมของผลิตภัณฑ์สำเร็จรูป

● การทำแม่พิมพ์:เหมาะอย่างยิ่งสำหรับการผลิตแม่พิมพ์ โดยเฉพาะในอุตสาหกรรมต่างๆ เช่น อุตสาหกรรมยานยนต์และการบินและอวกาศ ที่ชิ้นส่วนขนาดใหญ่ต้องผ่านการประมวลผลด้วยความแม่นยำสูง

● อุปกรณ์หนัก:ใช้ในการกลึงชิ้นส่วนอุตสาหกรรมหนักที่ต้องการความแข็งแรงและเสถียรภาพสูง

เครื่องเจาะและกัด CNC ผสานรวมความสามารถในการเจาะและกัดไว้ในเครื่องเดียว เครื่องไฮบริดนี้ช่วยให้ผู้ผลิตสามารถดำเนินการหลายอย่างได้ เช่น การเจาะรูและการตัดรูปทรง โดยไม่ต้องสลับไปมาระหว่างเครื่องต่างๆ

● การทำงานแบบคู่:สามารถเจาะรู ตัดรูปทรง และดำเนินการงานกัดที่ซับซ้อน ทำให้เป็นโซลูชันอเนกประสงค์สำหรับความต้องการการผลิตที่หลากหลาย

● เพิ่มประสิทธิภาพ:การรวมฟังก์ชันทั้งสองไว้ในเครื่องเดียวช่วยลดเวลาในรอบการทำงานและเพิ่มปริมาณงาน ซึ่งเป็นประโยชน์อย่างยิ่งในการผลิตปริมาณมาก

● ความแม่นยำ:เช่นเดียวกับเครื่อง CNC อื่นๆ เครื่องนี้ยังคงความแม่นยำสูงทั้งในการกัดและการเจาะ

● ประสิทธิภาพพื้นที่:ประหยัดพื้นที่และการลงทุนด้วยการรวมสองฟังก์ชั่นไว้ในเครื่องเดียว

● ลดเวลาในการตั้งค่า:ความสามารถในการดำเนินการทั้งการกัดและการเจาะในการตั้งค่าเดียวช่วยปรับปรุงประสิทธิภาพการผลิตโดยรวม

● ความยืดหยุ่น:เหมาะสำหรับผู้ผลิตที่ต้องดำเนินการทั้งสองอย่างเป็นประจำ

● ชิ้นส่วนยานยนต์:ใช้สำหรับงานกลึงชิ้นส่วนยานยนต์ที่ต้องอาศัยทั้งการเจาะและการกัด เช่น ชิ้นส่วนเครื่องยนต์และขายึด

● การบินและอวกาศและการทหาร:มักพบในอุตสาหกรรมที่ต้องการความแม่นยำสูงทั้งในงานเจาะและการกัด เช่น อุตสาหกรรมการบินและอวกาศและการป้องกันประเทศ

เครื่องกัด CNC อเนกประสงค์ผสานรวมฟังก์ชันการทำงานของเครื่องกัดทั้งแบบแนวตั้งและแนวนอน ทำให้ผู้ปฏิบัติงานสามารถทำงานต่างๆ ได้หลากหลายบนชิ้นงานที่แตกต่างกัน ความคล่องตัวทำให้เครื่องนี้เป็นตัวเลือกที่ยอดเยี่ยมสำหรับงานขนาดเล็กถึงขนาดกลาง

● ฟังก์ชั่นคู่:สามารถใช้งานได้ทั้งแนวตั้งและแนวนอน ทำให้มีความยืดหยุ่นสูงสำหรับงานตัดเฉือนที่หลากหลาย

● การควบคุมด้วยมือและ CNC:เครื่องจักรเหล่านี้มักควบคุมทั้งด้วยมือและ CNC ซึ่งช่วยให้เกิดความสมดุลระหว่างความคล่องตัวและระบบอัตโนมัติ

● โต๊ะหมุน:เครื่องบดอเนกประสงค์หลายรุ่นมีโต๊ะหมุน ช่วยให้ผู้ปฏิบัติงานวางชิ้นงานในมุมต่างๆ เพื่อการเข้าถึงที่ดีขึ้น

● ความสามารถในการปรับตัว:สามารถจัดการงานหลากหลาย ตั้งแต่การเจาะจนถึงการกัดที่ซับซ้อน โดยให้ความหลากหลายเป็นพิเศษในเครื่องเดียว

● คุ้มค่าคุ้มราคา:รวมเอาข้อดีของเครื่องบดทั้งแนวตั้งและแนวนอนเข้าไว้ด้วยกันในต้นทุนต่ำกว่าการมีเครื่องจักรแยกกัน

● ความสะดวกในการติดตั้ง:เครื่องจักรสามารถกำหนดค่าใหม่ได้อย่างรวดเร็วสำหรับงานประเภทต่างๆ ทำให้เหมาะสำหรับการเปลี่ยนแปลงอย่างรวดเร็ว

● การสร้างต้นแบบและการผลิตแบบกำหนดเอง:เหมาะสำหรับการเปลี่ยนแปลงอย่างรวดเร็วในการผลิตและชิ้นส่วนครั้งเดียวหรือแบบกำหนดเอง

● งานกลึงทั่วไป:ใช้ในอุตสาหกรรมต่างๆ มากมาย เช่น ทางการแพทย์ ยานยนต์ และการผลิตทั่วไป สำหรับการใช้งานที่หลากหลาย

เครื่องกัดเราเตอร์ CNC ออกแบบมาเพื่อการตัดวัสดุอ่อน เช่น ไม้ พลาสติก และวัสดุผสมโดยเฉพาะ นอกจากนี้ยังสามารถแกะสลักลวดลายที่ซับซ้อนบนวัสดุเหล่านี้ได้อย่างแม่นยำ ทำให้เป็นเครื่องมือทั่วไปในอุตสาหกรรมที่เน้นการผลิตป้าย การผลิตเฟอร์นิเจอร์ และต้นแบบ

● เครื่องมือตัดแบบโรตารี่:เครื่องจักรนี้ใช้เครื่องมือตัดแบบหมุนซึ่งให้ความสามารถในการแกะสลักลวดลายบนวัสดุแบนได้

● แกนหมุนความเร็วสูง:แกนหมุนสามารถหมุนด้วยความเร็วสูงมาก จึงมีประสิทธิภาพในการตัดและแกะสลักบนวัสดุที่อ่อนกว่า

● ความอเนกประสงค์:เราเตอร์ CNC สามารถรองรับวัสดุได้หลากหลาย ตั้งแต่ไม้และพลาสติก ไปจนถึงโลหะเบาบางชนิด เช่น อะลูมิเนียม

● คุ้มค่าสำหรับวัสดุที่อ่อนนุ่ม:เราเตอร์ CNC มักจะมีราคาถูกกว่าเครื่อง CNC ประเภทอื่น ทำให้เหมาะกับร้านค้าขนาดเล็กและงานสั่งทำพิเศษ

● รายละเอียดและความซับซ้อน:ความแม่นยำสูงของเราเตอร์ CNC ช่วยให้สามารถผลิตการตัดที่มีรายละเอียดและการออกแบบที่ซับซ้อนได้

● ความสะดวกในการใช้งาน:โดยทั่วไปแล้วเครื่องจักรเหล่านี้ใช้งานง่ายกว่าเมื่อเปรียบเทียบกับเครื่องกัด CNC ขนาดใหญ่ จึงทำให้เหมาะกับการใช้งานขนาดเล็ก

● ป้ายบอกทาง:ใช้ทั่วไปในการสร้างป้ายและการแสดงที่กำหนดเอง

● เฟอร์นิเจอร์และตู้เก็บของ:ใช้ในงานไม้เพื่อตัดและแกะสลักรูปทรงที่ซับซ้อน

● การสร้างต้นแบบ:เราเตอร์ CNC มักใช้ในการสร้างต้นแบบสำหรับอุตสาหกรรมต่างๆ เช่น ยานยนต์และการสร้างแบบจำลองทางสถาปัตยกรรม

ศูนย์เครื่องจักรกลแนวตั้ง (VMC) คือเครื่องกัดแนวตั้งขั้นสูงที่ผสานรวมคุณลักษณะอัตโนมัติ เช่น ตัวเปลี่ยนเครื่องมืออัตโนมัติ แกนเครื่องมือ และระบบควบคุมขั้นสูง ซึ่งทำให้ VMC เหมาะอย่างยิ่งสำหรับการตัดเฉือนชิ้นส่วนที่ซับซ้อนด้วยความแม่นยำสูง

● เครื่องเปลี่ยนเครื่องมืออัตโนมัติ (ATC):VMC มักมาพร้อมกับเครื่องเปลี่ยนเครื่องมืออัตโนมัติ ซึ่งทำให้สามารถใช้เครื่องมือหลายชิ้นได้โดยไม่ต้องดำเนินการด้วยตนเอง

● ความแม่นยำ:เช่นเดียวกับโรงสีแนวตั้งอื่นๆ VMC ยังคงรักษาความแม่นยำสูงไว้ แต่ได้รับการปรับปรุงด้วยระบบอัตโนมัติและคุณลักษณะขั้นสูงที่ช่วยให้สามารถผลิตชิ้นส่วนที่มีความซับซ้อนและปริมาณมากได้อย่างรวดเร็วและแม่นยำ

● แกนหมุนความเร็วสูง:VMC มีแกนหมุนความเร็วสูงที่สามารถให้ชิ้นงานมีความละเอียดและเรียบเนียน จึงเหมาะอย่างยิ่งสำหรับอุตสาหกรรมที่ต้องการความแม่นยำ

● เพิ่มผลผลิต:ด้วยคุณสมบัติเช่น ATC และแกนหมุนความเร็วสูง VMC จึงสามารถทำงานด้วยความเร็วที่สูงขึ้นและแม่นยำยิ่งขึ้น

● การกลึงที่ซับซ้อน:VMC เหมาะอย่างยิ่งสำหรับการผลิตชิ้นส่วนที่มีเรขาคณิตที่ซับซ้อน ลดความจำเป็นในการใช้เครื่องจักรและการตั้งค่าหลายเครื่อง

● ลดเวลาการทำงานการผสานรวมซอฟต์แวร์ขั้นสูงและคุณลักษณะอัตโนมัติช่วยลดเวลาในการตั้งค่าและการทำงาน ส่งผลให้ประสิทธิภาพเพิ่มมากขึ้น

● การบินและอวกาศและการป้องกันประเทศ:มักใช้ในการผลิตชิ้นส่วนอากาศยานที่ต้องการความแม่นยำ เช่น ใบพัดกังหัน และส่วนประกอบโครงสร้าง

● อุปกรณ์ทางการแพทย์:เหมาะสำหรับการผลิตชิ้นส่วนที่มีรายละเอียดและซับซ้อนที่จำเป็นสำหรับอุปกรณ์ปลูกถ่ายทางการแพทย์ เครื่องมือ และอุปกรณ์ทางการผ่าตัด

● ยานยนต์:ใช้ในการผลิตยานยนต์สำหรับชิ้นส่วนที่ต้องการรายละเอียดประณีต เช่น ชิ้นส่วนเครื่องยนต์และตัวเรือนเกียร์

ศูนย์เครื่องจักรกลซีเอ็นซีแนวนอน (HMC) มีลักษณะคล้ายกับเครื่องกัดซีเอ็นซีแนวนอน แต่มีคุณสมบัติอัตโนมัติ เช่น เครื่องเปลี่ยนเครื่องมืออัตโนมัติ (ATC) และโต๊ะหมุน HMC ได้รับการปรับให้เหมาะสมสำหรับงานกลึงที่มีปริมาณมากและมีความแม่นยำสูง

● แกนหมุนแนวนอนพร้อมตัวเปลี่ยนเครื่องมืออัตโนมัติ:แกนหมุนแนวนอนช่วยให้กำจัดเศษโลหะได้อย่างมีประสิทธิภาพ ในขณะที่ ATC ลดเวลาหยุดทำงานให้น้อยที่สุดด้วยการเปลี่ยนเครื่องมืออัตโนมัติ

● ความสามารถหลายแกน:HMC บางเครื่องมีแกนหมุนเพิ่มเติมเพื่อให้สามารถทำงานกลึง 4 หรือ 5 แกนได้ในการตั้งค่าเดียว ช่วยเพิ่มประสิทธิภาพการผลิตและความยืดหยุ่น

● ความเสถียรสำหรับชิ้นส่วนหนัก:การจัดวางแนวนอนจะมีเสถียรภาพมากขึ้น ซึ่งเป็นประโยชน์อย่างยิ่งเมื่อทำงานกับวัสดุขนาดใหญ่และหนัก

● การผลิตปริมาณสูง:HMC เหมาะอย่างยิ่งสำหรับอุตสาหกรรมที่ต้องการชิ้นส่วนคุณภาพสูงและสม่ำเสมอในปริมาณมาก เช่น อุตสาหกรรมยานยนต์และการบินและอวกาศ

● เวลาหยุดทำงานน้อยลง:ระบบเปลี่ยนเครื่องมืออัตโนมัติและระบบกำจัดเศษที่มีประสิทธิภาพช่วยลดเวลาหยุดทำงานระหว่างการปฏิบัติงาน

● เพิ่มความแม่นยำ:ความเสถียรที่ได้รับจากการตั้งค่าแนวนอนทำให้มีความแม่นยำสูงขึ้นเมื่อต้องกลึงชิ้นส่วนขนาดใหญ่

● การบินและอวกาศ:มักใช้ในการผลิตชิ้นส่วนอากาศยานขนาดใหญ่และซับซ้อน เช่น โครงเครื่องบิน โครงสร้างปีก และส่วนประกอบเครื่องยนต์

● ยานยนต์:เหมาะอย่างยิ่งสำหรับการกลึงบล็อคเครื่องยนต์ ชิ้นส่วนส่งกำลัง และส่วนประกอบโครงสร้างสำหรับการผลิตจำนวนมาก

● การผลิตอุปกรณ์หนัก:มักใช้สำหรับชิ้นส่วนในเครื่องจักรกลหนักและภาคการก่อสร้างที่ต้องการความเสถียรและความแม่นยำ

เครื่องกัดซีเอ็นซีแบบเตียงมีลักษณะเด่นคือชิ้นงานนิ่งที่ยึดแน่นบนเตียงขนาดใหญ่ที่มั่นคง เครื่องมือตัดจะเคลื่อนตัวไปเหนือชิ้นงาน ทำให้เครื่องนี้เหมาะอย่างยิ่งสำหรับการกัดชิ้นงานขนาดใหญ่ด้วยความแม่นยำ

● การก่อสร้างแบบใช้งานหนัก:ฐานเตียงมีความแข็งแรงที่จำเป็นเพื่อรองรับชิ้นส่วนขนาดใหญ่และหนักในระหว่างการตัด ช่วยให้ตัดได้แม่นยำและมีคุณภาพสูง

● ระยะทางการเดินทางไกล:เครื่องจักรเหล่านี้สามารถเคลื่อนที่ได้ในระยะทางไกล ช่วยให้ทำงานกับชิ้นส่วนที่ยาวขึ้นหรือใหญ่ขึ้นได้

● ความแม่นยำสูง:แม้ว่าเครื่องกัด CNC แบบแท่นจะมีขนาดใหญ่ แต่ก็สามารถทำงานด้วยความแม่นยำสูงได้ ซึ่งทำให้เครื่องกัดเหล่านี้เหมาะกับอุตสาหกรรมที่ต้องการรายละเอียดเล็กๆ น้อยๆ บนชิ้นส่วนขนาดใหญ่

● การจัดการชิ้นส่วนขนาดใหญ่:การออกแบบเตียงช่วยให้เครื่องจักรสามารถรองรับชิ้นงานขนาดใหญ่ จึงทำให้เหมาะอย่างยิ่งสำหรับการตัดเฉือนชิ้นส่วนที่มีขนาดใหญ่มาก

● เพิ่มเสถียรภาพโครงสร้างที่แข็งแกร่งของเครื่องจักรช่วยลดการสั่นสะเทือน ทำให้มีเสถียรภาพและความแม่นยำที่มากขึ้นเมื่อทำงานกับวัสดุขนาดใหญ่หรือหนัก

● ขยายระยะการเข้าถึงเครื่องมือ:โดยทั่วไปแล้วเครื่องบดแบบแท่นสามารถทำงานกับเครื่องมือขนาดใหญ่ได้ และสามารถเข้าถึงพื้นที่ที่เครื่องบดแนวตั้งไม่สามารถเข้าถึงได้

● เครื่องจักรกลหนัก:ใช้ในการกลึงชิ้นส่วนขนาดใหญ่ในอุตสาหกรรม เช่น อุตสาหกรรมเหมืองแร่และก่อสร้าง

● การผลิตแม่พิมพ์:เหมาะสำหรับการผลิตแม่พิมพ์และแม่พิมพ์ที่ต้องการทั้งขนาดและความแม่นยำ

● ยานยนต์:มักใช้ในการผลิตชิ้นส่วนยานยนต์ขนาดใหญ่ เช่น โครงรถ ตัวถังรถ และชิ้นส่วนเครื่องยนต์

เครื่องกลึง CNC แบบ Turn-Mill ผสานรวมทั้งการกลึงและการกัดเข้าเป็นหน่วยเดียว ทำให้ผู้ผลิตสามารถดำเนินการทั้งสองประเภทพร้อมกันได้ ฟังก์ชันไฮบริดนี้เป็นประโยชน์อย่างยิ่งสำหรับชิ้นส่วนที่ซับซ้อนซึ่งต้องใช้ทั้งการกลึง (การตัดแบบหมุน) และการกัด (การตัดเชิงเส้น)