ระบบอัตโนมัติของ CNC เป็นศูนย์กลางของการพัฒนาอย่างต่อเนื่องและวิธีที่เราสร้างสิ่งต่างๆ การสร้างภาพพลังคอมพิวเตอร์ที่มากขึ้นเบื้องหลังการผลิตสมัยใหม่: การควบคุมเครื่องจักรที่แม่นยำและระบบอัตโนมัติขั้นสูงที่ออกแบบมาเพื่อให้ทำงานได้อย่างชาญฉลาดยิ่งขึ้น ไม่ใช่หนักขึ้น

ระบบอัตโนมัติของ CNC กำลังเปลี่ยนอุตสาหกรรมจากการประกอบอุปกรณ์ทางการแพทย์ที่ซับซ้อนไปสู่การสร้างการใช้งานเฟอร์นิเจอร์ตามสั่งเพื่อประสิทธิภาพ ความแม่นยำ และความสามารถในการปรับตัว การประหยัดเวลาไม่ใช่เป้าหมายเดียวเท่านั้น แต่ยังช่วยให้บรรลุผลสำเร็จเร็วขึ้น ดีขึ้น และปลอดภัยยิ่งขึ้น เทคโนโลยีนี้ได้กลายเป็นอาวุธลับในการเป็นผู้นำในเกม ไม่ว่าคุณจะสร้างรถยนต์หรือประดิษฐ์ไมโครชิปขนาดเล็กก็ตาม

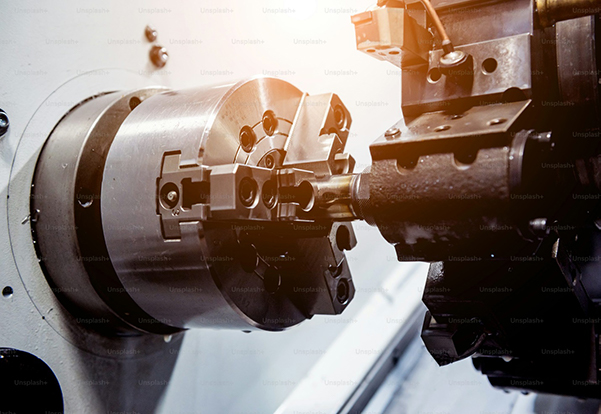

ระบบอัตโนมัติ CNC หมายถึงการใช้ซอฟต์แวร์คอมพิวเตอร์เพื่อควบคุมการเคลื่อนที่ของเครื่องมือกลในกระบวนการผลิต แตกต่างจากการตัดเฉือนด้วยมือแบบดั้งเดิม เครื่องซีเอ็นซี ดำเนินการตามลำดับคำสั่งที่ตั้งโปรแกรมไว้ล่วงหน้าเพื่อให้ได้ผลลัพธ์ที่สม่ำเสมอและแม่นยำ เมื่อใช้ร่วมกับระบบอัตโนมัติ ระบบ CNC สามารถทำงานได้โดยปราศจากการแทรกแซงจากมนุษย์โดยตรง ซึ่งช่วยยกระดับกระบวนการผลิตให้ดียิ่งขึ้น

ด้วยแขนหุ่นยนต์ ทำให้เครื่องจักร CNC มีเซ็นเซอร์และเทคโนโลยีอัจฉริยะ และสามารถทำงานที่ซับซ้อนได้ด้วยตัวเอง ในอุตสาหกรรมการบินและอวกาศ ยานยนต์ อิเล็กทรอนิกส์ ชีวการแพทย์ และอุตสาหกรรมอื่นๆ ที่ความแม่นยำและประสิทธิภาพเป็นสิ่งเดียวที่สำคัญ ระบบเหล่านี้จึงถูกนำมาใช้กันอย่างแพร่หลาย

ระบบอัตโนมัติ CNC ช่วยให้กระบวนการผลิตดำเนินไปได้อย่างราบรื่นยิ่งขึ้น ด้วยต้นทุนที่ต่ำกว่า และผลลัพธ์ที่สม่ำเสมอ การบูรณาการสามารถบรรลุมาตรฐานสูงสุดที่ธุรกิจสามารถทำให้ตัวเองแข่งขันได้ในอุตสาหกรรมที่เคลื่อนไหวอย่างรวดเร็ว

ข้อได้เปรียบที่สำคัญที่สุดของระบบอัตโนมัติ CNC คือเป็นตัวช่วยเพิ่มประสิทธิภาพการผลิต สามารถทำงานได้ตลอดหลายชั่วโมง ลดการหยุดทำงานและเพิ่มผลผลิตสูงสุด เครื่องจักร CNC อัตโนมัติไม่จำเป็นต้องหยุดพักและสามารถสร้างชิ้นส่วนได้อย่างต่อเนื่อง ตอบสนองความต้องการสูงได้อย่างง่ายดาย

นอกจากนี้ ระบบอัตโนมัติของ CNC จะประมวลผลการดำเนินการได้เร็วกว่าแบบแมนนวล ผู้ผลิตสามารถเร่งการดำเนินงานของตนและปรับใช้พนักงานของตนให้มีมูลค่าสูงสุดในบทบาทเชิงกลยุทธ์มากขึ้นโดยทำให้เป็นอัตโนมัติหรือกำจัดงานที่ซ้ำกัน

มันเป็นสิ่งสำคัญในการผลิต การเบี่ยงเบนเล็กน้อยไม่ว่าขนาดใดก็ตามเป็นสิ่งที่ยอมรับไม่ได้สำหรับอุตสาหกรรมการบินและอวกาศและอุปกรณ์การแพทย์ คุณสมบัติการทำงานอัตโนมัติของ CNC ประการหนึ่งคือการดำเนินการคำสั่งตามการตั้งโปรแกรมที่แน่นอน และไม่มีข้อผิดพลาดจากมนุษย์ที่สามารถลดความแม่นยำได้

เครื่องจักร CNC ที่ทันสมัยส่วนใหญ่มีเซ็นเซอร์และระบบตรวจสอบขั้นสูงที่ช่วยให้สามารถปรับแบบเรียลไทม์ได้อย่างง่ายดายเพื่อรักษาพิกัดความเผื่อที่แคบ ผลิตภัณฑ์คุณภาพสูง ของเสียน้อยลง และลูกค้ามีความสุขเป็นผลมาจากความแม่นยำระดับนี้

ระบบอัตโนมัติ CNC ขึ้นชื่อเรื่องความสม่ำเสมอ ความแตกต่างระหว่างชิ้นส่วนต่างๆ เนื่องจากทักษะของผู้ปฏิบัติงานที่แตกต่างกันหรือความล้าเป็นเรื่องปกติของการตัดเฉือนด้วยมือ อย่างไรก็ตาม ระบบอัตโนมัติของ CNC หมายความว่าแต่ละชิ้นส่วนจะเหมือนกัน ไม่ว่าจะผลิตกี่ชิ้นก็ตาม

ในอุตสาหกรรมการผลิตจำนวนมาก การทำซ้ำมีความหมายอย่างมาก เนื่องจากเราต้องการให้ทุกอย่างเหมือนกัน ด้วยระบบอัตโนมัติ CNC คุณจะได้ผลลัพธ์ที่สม่ำเสมอ คุณจะสร้างความไว้วางใจกับลูกค้าของคุณ และโอกาสที่จะเกิดข้อบกพร่องก็น้อยลงมาก มันเป็นเพียงวิธีที่ถูกกว่าในการสร้างและสามารถช่วยให้ผู้ใช้ทั่วไปเข้าถึงได้มากขึ้น

ในการผลิต ต้นทุนแรงงานถือเป็นค่าใช้จ่ายหลัก และการประยุกต์ใช้ระบบอัตโนมัติ CNC ในทางปฏิบัติสามารถลดต้นทุนแรงงานเหล่านี้ได้ ระบบอัตโนมัติช่วยลดความจำเป็นในการใช้แรงงานคน และลดขนาดพนักงาน แต่การบำรุงรักษาหรือการเติบโตของการผลิตไม่ได้ถูกขัดขวางแม้แต่น้อย

ในกรณีของระบบอัตโนมัติ CNC การลงทุนเริ่มแรกในเทคโนโลยีดังกล่าวอาจสร้างความเสียหายให้กับบริษัทได้ แต่จะช่วยประหยัดต้นทุนได้มากในระยะยาว ผู้ผลิตสามารถทำกำไรได้มากขึ้นโดยลดการพึ่งพาช่างเครื่องที่มีทักษะและแรงงานที่ซ้ำซ้อน

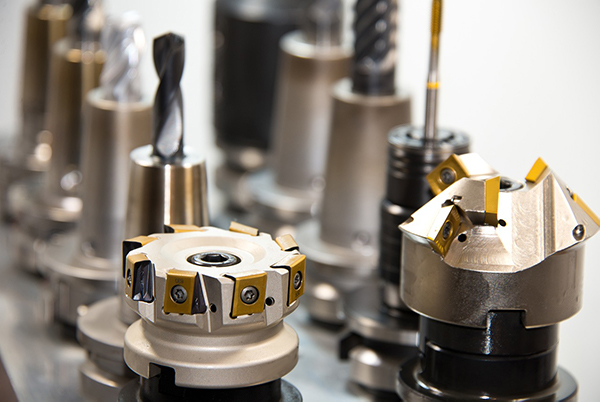

ระบบอัตโนมัติ CNC ช่วยให้คุณทำการเปลี่ยนแปลงอย่างรวดเร็วในตลาดที่กำลังเคลื่อนไหว มอบความยืดหยุ่นที่ไม่มีใครเทียบได้ มีเครื่องจักร CNC หลายชนิดที่สามารถตั้งโปรแกรมให้ทำงานอื่นๆ ได้หลากหลาย รวมถึงการตัดและเจาะที่น่าเบื่อน้อยลง และแม้แต่โมเดลการตัดเฉือน 3D ที่ซับซ้อนที่สุด

ความสามารถในการปรับตัวช่วยให้คุณย้ายจากโครงการหนึ่งไปอีกโครงการหนึ่งได้อย่างรวดเร็ว หรือปรับแต่งผลิตภัณฑ์ให้ตรงตามความต้องการที่กำหนด ในอุตสาหกรรมที่มีการเปลี่ยนแปลงการออกแบบบ่อยครั้ง ระบบอัตโนมัติของ CNC จะปกป้องผู้ผลิตจากความล่าช้าในด้านความคล่องตัวและตอบสนองต่อการเปลี่ยนแปลงในความต้องการของตลาด

ในสภาพแวดล้อมการผลิตใดๆ ความปลอดภัยในสถานที่ทำงานถือเป็นสิ่งสำคัญอันดับหนึ่ง และนั่นเป็นข้อดีอย่างมากของระบบอัตโนมัติ CNC ซึ่งก็คือความเสี่ยงที่จะเกิดอุบัติเหตุ พวกเขาทำงานที่เป็นอันตราย เช่น การยกของหนักหรือการสัมผัสกับวัสดุอันตราย และผู้ปฏิบัติงานที่เป็นมนุษย์ไม่จำเป็นต้องอยู่ใกล้กับกิจกรรมที่เป็นอันตราย

เครื่องจักร CNC มักมีคุณสมบัติด้านความปลอดภัยในตัว เช่น กลไกการหยุดฉุกเฉินและกรอบป้องกัน ซึ่งทั้งหมดนี้ช่วยปรับปรุงสภาพการทำงานและความปลอดภัยของผู้ปฏิบัติงาน ประการแรก ธุรกิจสามารถลดต้นทุนการประกันภัยและเพิ่มขวัญกำลังใจได้ หากสามารถลดอุบัติเหตุจากการทำงานโดยอุบัติเหตุได้

ระบบอัตโนมัติ CNC ช่วยลดแรงงาน ลดระยะเวลาวงจรการผลิตลง และช่วยให้ผู้ผลิตสามารถทำงานให้เสร็จตามกำหนดเวลาที่จำกัดได้ เวลาการตั้งค่าจะลดลงและไม่ต้องปรับเปลี่ยนด้วยตนเอง เนื่องจากระบบอัตโนมัติช่วยให้มั่นใจได้ว่าการดำเนินการผลิตจะเสร็จสิ้นอย่างมีประสิทธิภาพ

สำหรับอุตสาหกรรมที่บริษัททำงานร่วมกับห่วงโซ่อุปทานแบบไดนามิก ซึ่งความล่าช้าแม้แต่มิลลิวินาทีก็สามารถส่งผลกระทบในวงกว้างได้ ความเร็วที่รวดเร็วนี้มีประโยชน์มาก ระบบอัตโนมัติ CNC ช่วยให้ธุรกิจสามารถแข่งขันได้ เนื่องจากใช้เวลาน้อยลงในการตอบสนองความคาดหวังของลูกค้า

ความต้องการการผลิตในธุรกิจมักจะสูงขึ้นเมื่อธุรกิจเติบโตขึ้น และระบบอัตโนมัติของ CNC ช่วยให้พวกเขาขยายขนาดการผลิตได้ ง่ายต่อการขยายขนาดและขยายการดำเนินงานด้วยระบบอัตโนมัติ เนื่องจากสามารถปรับขนาดเพื่อรองรับปริมาณที่เพิ่มขึ้นและอัปเกรดตามนั้นได้อย่างง่ายดาย

นอกจากนี้ ระบบอัตโนมัติ CNC ยังช่วยให้ผู้ผลิตสามารถผลิตการผลิตทั้งขนาดเล็กและขนาดใหญ่ได้อย่างเท่าเทียมกัน เพื่อพัฒนาชุดการแข่งขันในอุตสาหกรรมต่างๆ ความสามารถในการขยายขนาดดังกล่าวไม่มีค่าสำหรับธุรกิจที่ต้องการเติบโตหรือปรับตัวให้เข้ากับการเปลี่ยนแปลงของตลาดด้านข้าง

ความสามารถในการลดการหยุดทำงานของการบำรุงรักษาถือเป็นหนึ่งในข้อดีของระบบอัตโนมัติ CNC ที่มักถูกมองข้าม อย่างไรก็ตาม เครื่องจักร CNC ในปัจจุบันมีระบบตรวจสอบที่ซับซ้อน ซึ่งจะช่วยระบุปัญหาการผลิตเบียร์ก่อนที่จะสายเกินไป

คุณสมบัติการบำรุงรักษาเชิงคาดการณ์ช่วยให้ผู้ผลิตแก้ไขปัญหาได้ก่อนที่จะเกิดขึ้น โดยกำหนดเวลาการซ่อมแซมที่มีปัญหานอกเวลาทำการเพื่อหลีกเลี่ยงการหยุดทำงานของระบบ ขั้นตอนการผลิตที่ราบรื่นยิ่งขึ้น ผลผลิตที่เชื่อถือได้มากขึ้น และการหยุดชะงักของกำหนดเวลาโครงการที่จำกัดน้อยลง เป็นผลมาจากการหยุดทำงานที่น้อยลง

แม้ว่าการเข้าสู่ระบบอัตโนมัติ CNC อาจดูมีค่าใช้จ่ายสูงกว่าในตอนแรก แต่ก็มีการจ่ายเงินในระยะยาว โปรดจำไว้ว่าการลดต้นทุนแรงงานโดยอัตโนมัติ กำลังการผลิตที่เพิ่มขึ้น และลดของเสีย ซึ่งจะช่วยประหยัดได้มากในระยะยาว

นอกจากนี้ ยังช่วยเพิ่มคุณภาพการผลิตและความรู้ความชำนาญทางธุรกิจ ซึ่งส่งผลให้ลูกค้ามีความพึงพอใจมากขึ้นและกลับมาทำธุรกิจซ้ำ ระบบอัตโนมัติของ CNC ถือเป็นอัตราผลตอบแทนจากการลงทุนด้านการผลิตที่ดีที่สุดอัตราหนึ่ง ช่วยให้ผู้ผลิตสามารถปรับขนาดได้อย่างมีประสิทธิภาพและรักษาความสามารถในการแข่งขันได้

ระบบอัตโนมัติ CNC เป็นเทคโนโลยีที่เปลี่ยนแปลงเกมซึ่งได้กำหนดนิยามใหม่ของประสบการณ์การผลิต สาเหตุหนึ่งที่ทำให้สิ่งนี้เป็นรากฐานที่สำคัญในหลายอุตสาหกรรมก็คือ นำเสนอความแม่นยำและประสิทธิภาพสูง ควบคู่ไปกับความสามารถในการปรับตัว ซึ่งช่วยให้ธุรกิจต่างๆ สามารถตอบสนองข้อจำกัดด้านความต้องการที่ซับซ้อนและบรรลุมาตรฐานการผลิตที่มีคุณภาพได้มาตรฐานในระดับสูง

ระบบอัตโนมัติ CNC เป็นหนึ่งในคุณประโยชน์หลักของอุตสาหกรรมยานยนต์ ปรากฎว่าเครื่องจักร CNC เป็นแหล่งที่สำคัญมากในการผลิตชิ้นส่วนที่สำคัญดังกล่าว ตั้งแต่เครื่องยนต์และระบบส่งกำลัง ไปจนถึงชิ้นส่วนแชสซี เครื่องจักรเหล่านี้สามารถทำงานได้ภายใต้พิกัดความเผื่อที่จำกัด โดยเป็นไปตามข้อกำหนดด้านความปลอดภัยและประสิทธิภาพที่เข้มงวดของการผลิตยานยนต์

นอกจากนี้ ระบบอัตโนมัติ CNC ยังช่วยให้สามารถผลิตชิ้นส่วนที่ต้องดำเนินการเป็นประจำเป็นจำนวนมาก ซึ่งมีต้นทุนควบคู่ไปกับประสิทธิภาพการผลิต นอกจากนี้ยังสามารถปรับให้เข้ากับการออกแบบที่กำหนดเองได้ ซึ่งสนับสนุนความต้องการที่เพิ่มขึ้นของผู้ผลิตในการตอบสนองคำขอของยานพาหนะแบบกำหนดเองโดยไม่กระทบต่อประสิทธิภาพการผลิต

ระบบอัตโนมัติ CNC เป็นโซลูชั่นที่สมบูรณ์แบบสำหรับข้อกำหนดที่เข้มงวดของการผลิตด้านการบินและอวกาศ ความแม่นยำคือทุกสิ่ง สินค้าที่ผลิตด้วยเทคโนโลยีดังกล่าว ได้แก่ ใบพัดกังหัน เคสเครื่องยนต์ และส่วนประกอบโครงสร้างเครื่องบินอื่นๆ ชิ้นส่วนเหล่านี้ต้องการข้อกำหนดเฉพาะและการดำเนินการที่สมบูรณ์แบบ ซึ่ง CNC Automation จัดเตรียมไว้ให้อย่างสม่ำเสมอ

ระบบอัตโนมัติก้าวไปไกลกว่าความแม่นยำในการปรับปรุงประสิทธิภาพการผลิตอย่างมากโดยทำให้ขั้นตอนการผลิตเป็นแบบอัตโนมัติ ช่วยให้มั่นใจได้ว่ามีการปฏิบัติตามมาตรฐานประสิทธิภาพและความปลอดภัยระดับสูงพร้อมทั้งลดเวลาในการผลิตให้เหลือน้อยที่สุด ซึ่งเป็นข้อได้เปรียบที่สำคัญในอุตสาหกรรมที่อาจมีผลกระทบและความล่าช้าทางการเงินและการดำเนินงานอย่างมาก

การย่อขนาดและความแม่นยำเป็นตัวกำหนดอุตสาหกรรมอิเล็กทรอนิกส์ และระบบอัตโนมัติ CNC เป็นสิ่งจำเป็น เครื่องจักร CNC ใช้เพื่อสร้างความแม่นยำที่ไม่มีใครเทียบได้กับส่วนประกอบต่างๆ เช่น แผงวงจรพิมพ์ (PCB) ขั้วต่อ และกล่องหุ้มอิเล็กทรอนิกส์ รายละเอียดระดับนี้มอบความน่าเชื่อถือและฟังก์ชันการทำงานให้กับอุปกรณ์ที่มีขนาดเล็กเท่ากับสมาร์ทโฟนและใหญ่เท่ากับอุปกรณ์คอมพิวเตอร์ขั้นสูง

ในตลาดโลกที่เต็มไปด้วยความต้องการอุปกรณ์อิเล็กทรอนิกส์ ระบบอัตโนมัติจะช่วยเร่งกระบวนการผลิตให้เร็วขึ้น ระบบอัตโนมัติ CNC ช่วยลดการแทรกแซงด้วยตนเองและอัตราข้อผิดพลาดเพื่อให้การผลิตคุ้มค่าด้วยมาตรฐานคุณภาพที่ไม่ธรรมดา

ผลิตภัณฑ์อุปกรณ์การแพทย์มีอิทธิพลอย่างมากต่อสุขภาพและชีวิตของผู้ป่วย ดังนั้นอุตสาหกรรมอุปกรณ์การแพทย์จึงต้องการความแม่นยำและความน่าเชื่อถือ การผลิตเครื่องมือผ่าตัด การปลูกถ่ายกระดูก และอุปกรณ์วินิจฉัย ครอบคลุมด้วยระบบอัตโนมัติ CNC อุปกรณ์ทางการแพทย์ของบริษัทจะต้องเป็นไปตามเกณฑ์ด้านกฎระเบียบที่เข้มงวด และความสามารถในการออกแบบการออกแบบที่ดีและรักษาระดับความคลาดเคลื่อนที่เข้มงวดอย่างยิ่งได้ทำให้เกิดความมั่นใจ

นอกจากนี้ CNC ยังช่วยให้สามารถผลิตโซลูชันทางการแพทย์แบบกำหนดเองได้ (เช่น การปลูกถ่ายเฉพาะผู้ป่วย) ซึ่งสามารถนำมาใช้ในการรักษาผู้ป่วยได้ดีขึ้น ระบบอัตโนมัติ CNC ได้กลายเป็นเทคโนโลยีหลักในการผลิตด้านการดูแลสุขภาพ โดยผสมผสานความสามารถเข้ากับมาตรการควบคุมคุณภาพที่มีความต้องการสูง

เทคโนโลยี CNC ได้เปลี่ยนแปลงอุตสาหกรรมเฟอร์นิเจอร์และงานไม้ไปอย่างมาก เราเตอร์ CNC แบบอัตโนมัติมีความสามารถในการแกะสลักอย่างละเอียด การตัดที่แม่นยำ และการออกแบบที่ซับซ้อน ซึ่งต้องทำด้วยตนเองและใช้ความพยายามพอสมควร เทคโนโลยีนี้สูงพอที่จะช่วยให้ผู้ผลิตเฟอร์นิเจอร์มีรูปร่างตามสั่งและหลากหลายรูปแบบ แม้จะเป็นแบบจำนวนมาก โดยไม่ต้องลดต้นทุนมากนัก

นอกจากนี้ ระบบอัตโนมัติ CNC ผ่านตัวเปลี่ยนเครื่องมืออัตโนมัติยังมีความแม่นยำ และไม่ทิ้งวัสดุเหลือทิ้งในการพัฒนา มีการเคลื่อนไหวค่อนข้างรวดเร็ว ซึ่งไม่เพียงแต่ช่วยลดต้นทุนการผลิตเท่านั้น แต่ยังเป็นกำลังใจสำหรับผู้บริโภคที่คำนึงถึงสิ่งแวดล้อมซึ่งโหยหาความยั่งยืนในการผลิตอีกด้วย

ผลกระทบต่อสิ่งแวดล้อมส่วนใหญ่จากการผลิตสามารถกำจัดได้ด้วยระบบอัตโนมัติ CNC ความแม่นยำจะป้องกันข้อผิดพลาดจากการผลิตเศษเหล็กและประหยัดวัสดุ นอกจากนี้ การนำวัสดุกลับมาใช้ใหม่จะช่วยลดการใช้พลังงานโดยทั่วไป และส่งผลให้การดำเนินงานมีความชาญฉลาดมากขึ้นโดยการใช้การควบคุมการปฏิบัติงานที่มีประสิทธิผล

ที่สำคัญกว่านั้น ระบบอัตโนมัติยังส่งเสริมการเข้าถึงวัสดุรีไซเคิลและกระบวนการผลิตที่ปลอดภัยที่สุดเท่าที่จะเป็นไปได้ ขึ้นอยู่กับระบบอัตโนมัติของ CNC มาก บรรลุขอบเขตที่อายุน้อยกว่าของการเพิ่มประสิทธิภาพทรัพยากรและการลดของเสีย และสามารถนำไปใช้ในวัฒนธรรมด้านสิ่งแวดล้อมของโรงงานได้

นี่หมายความว่าอนาคตของระบบอัตโนมัติ CNC ถูกกำหนดให้มีความก้าวหน้ามากขึ้นอย่างมากตามความก้าวหน้าของเทคโนโลยี แนวโน้มสำคัญ ได้แก่ :

• การบูรณาการปัญญาประดิษฐ์ (AI): ระบบ CNC ที่ขับเคลื่อนด้วย AI เพิ่มมากขึ้นเรื่อยๆ ช่วยให้สามารถบำรุงรักษาเชิงคาดการณ์ เพิ่มประสิทธิภาพแบบเรียลไทม์ และตัดสินใจได้อย่างชาญฉลาดยิ่งขึ้น

• Internet of Things (IoT): ด้วยการถือกำเนิดของเครื่องจักร CNC ที่ใช้ IoT การเชื่อมต่อและแบ่งปันข้อมูลกับเครื่องจักรและธุรกิจอื่นๆ จึงราบรื่น

• วัสดุขั้นสูง: ระบบอัตโนมัติของ CNC กำลังปรับตัวเพื่อประมวลผลวัสดุขั้นสูง เช่น คอมโพสิตและโพลีเมอร์ชีวภาพ ซึ่งกำลังเจาะลึกอุตสาหกรรมที่ล้ำสมัย

• การบูรณาการการผลิตแบบเติมเนื้อที่: การบูรณาการของ CNC และการพิมพ์ 3D แสดงให้เห็นถึงโอกาสพิเศษสำหรับกระบวนทัศน์การผลิตใหม่ ซึ่งให้ชิ้นส่วนที่ซับซ้อนสูงและให้ผลผลิตที่ดีขึ้น

• การมุ่งเน้นด้านความยั่งยืน: ระบบ CNC รุ่นใหม่จะเป็นมิตรกับสิ่งแวดล้อม และจะมุ่งเน้นไปที่อุตสาหกรรมสีเขียวโดยการลดการใช้พลังงานและนำแนวทางปฏิบัติที่สนับสนุน

แนวโน้มเหล่านี้ถูกกำหนดให้ระบบอัตโนมัติของ CNC อยู่ในจุดยืนของประสิทธิภาพ ความยืดหยุ่น และความสามารถในการปรับตัวที่ดีขึ้น เพื่อเพิ่มความยั่งยืนในปีต่อๆ ไป

ระบบอัตโนมัติ CNC ไม่ได้เป็นเพียงเครื่องมือเท่านั้น แต่การผสมผสานความคิดสร้างสรรค์เข้ากับความสามารถยังคงเป็นรากฐานสำคัญของการผลิตร่วมสมัย ซึ่งถือเป็นครั้งแรกในประวัติศาสตร์ของมนุษยชาติ หมายความว่าอุตสาหกรรมต่างๆ จะไม่มีวันมีความแม่นยำมากขึ้น ปรับขนาดได้ง่ายขึ้น หรือคงอยู่อีกต่อไป การพัฒนาอุปกรณ์ทางการแพทย์ที่สำคัญและการเปลี่ยนแปลงอุตสาหกรรมยานยนต์เป็นเพียงสองวิธีที่ระบบอัตโนมัติของ CNC กำลังเปลี่ยนเครื่องจักร CNC จากเครื่องมือการผลิตให้เป็นอะไรที่มากกว่านั้น ซึ่งเป็นสิ่งที่เรามองไม่เห็นด้วยซ้ำ

นี่ไม่ใช่กระแส แต่เป็นอนาคต และเราเพียงแต่เห็นสิ่งนี้เกิดขึ้นอย่างแข็งขัน ไม่ว่าจะมีขนาดเท่าใด ระบบอัตโนมัติของ CNC ก็ถือเป็นชีวิตแห่งอนาคตและเติบโตไปพร้อมๆ กับความเร็วและการเปลี่ยนแปลงที่เพิ่มขึ้นในธุรกิจปัจจุบัน นั่นหมายความว่าคุณต้องต้องการระบบอัตโนมัติ CNC

เมื่อมีการเพิ่มระบบอัตโนมัติลงในเครื่องมือ Computer Numerical Control (CNC) สิ่งนี้เรียกว่าระบบอัตโนมัติ CNC ระบบเหล่านี้ใช้คำสั่งที่ได้รับการตั้งโปรแกรมไว้แล้วให้ทำงานด้านการผลิตด้วยตัวเอง ซึ่งทำให้มีความแม่นยำและมีประสิทธิภาพมากขึ้น

เทคโนโลยี CNC ทำให้สิ่งต่างๆ มีประสิทธิภาพมากขึ้นโดยการลดเวลาหยุดทำงาน ของเสีย และความล่าช้าในการผลิต ระบบอัตโนมัติสามารถทำงานได้อย่างต่อเนื่อง สร้างสินค้าที่มีคุณภาพสม่ำเสมอ และลดความจำเป็นในการได้รับความช่วยเหลือจากมนุษย์

ระบบอัตโนมัติของ CNC มีประโยชน์มากในหลายสาขา รวมถึงรถยนต์ เครื่องบิน อิเล็กทรอนิกส์ อุปกรณ์ทางการแพทย์ และงานไม้ เพราะสามารถผลิตชิ้นส่วนคุณภาพสูงที่แม่นยำและแม่นยำได้จำนวนมากในคราวเดียว

การซื้อเครื่องจักร CNC การบูรณาการเทคโนโลยีระบบอัตโนมัติ (เช่น หุ่นยนต์และซอฟต์แวร์) และเจ้าหน้าที่การสอน ถือเป็นต้นทุนเริ่มต้นส่วนหนึ่งของระบบอัตโนมัติ CNC อาจมีค่าใช้จ่ายจำนวนมากล่วงหน้า แต่การประหยัดและผลผลิตที่เพิ่มขึ้นมักจะชดเชยได้

เพื่อแก้ไขปัญหา ธุรกิจควรชั่งน้ำหนักต้นทุนและผลประโยชน์อย่างรอบคอบ ฝึกอบรมพนักงาน และทำงานร่วมกับผู้จำหน่ายที่มีประสบการณ์เพื่อให้การดำเนินงานเป็นไปอย่างราบรื่น การเปลี่ยนแปลงยังสามารถทำได้ง่ายขึ้นโดยการนำเทคโนโลยีมาใช้อย่างช้าๆ และใช้ประโยชน์จากผลประโยชน์ของรัฐบาล